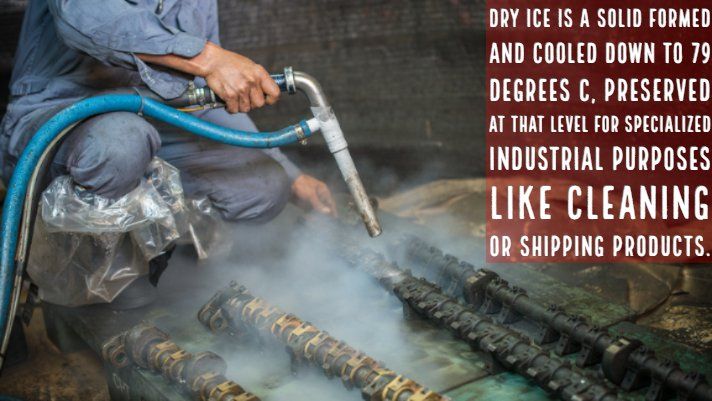

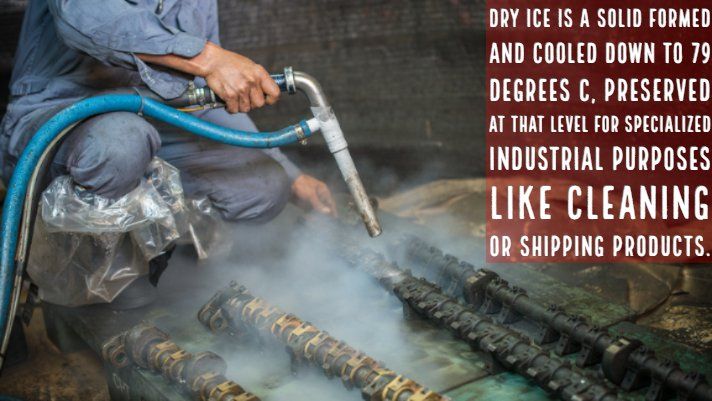

Food and beverage companies have to deal with strict safety and sanitation requirements. However, water cleaning and sandblasting do not offer a reliable cleaning method, especially when it comes to complex machinery. Dirt, germs, and other contaminants accumulate quickly, which is why food and beverage companies need a commercial cleaning company that is versed with the best cleaning method: dry ice blasting.

What is dry ice cleaning?

Dry ice blasting is a cleaning technique that uses carbon dioxide for cleaning purposes. The process involves accelerating dry carbon dioxide in a pressurized air stream and directing it towards the dirty surface for cleaning. This method of cleaning was patented in 1955 and has since been applied by electric companies, food and beverage companies, and chemical companies that don't find sand and water blasting as reliable cleaning solutions.

If you are looking for a commercial cleaning company, it would be good to consider a company that uses modern CO2 cleaning and CO2 cleaning equipment; you will get several benefits that you cannot get from a standard cleaning solution. Here are some of the top benefits of dry ice blasting cleaning.

1. Faster and More Efficient

There is no doubt that you are looking for a commercial cleaning company that will provide fast, efficient cleaning services. A company that uses dry ice blasting offers quality and efficiency that competitors just can't match. Advanced dry ice cleaning machines use supersonic speeds combined with cold temperatures to achieve a superior clean.

Most of the CO2 cleaning equipment doesn't need to be dis-assembled or re-assembled to start working. It is the role of the commercial cleaning company to make sure that the cleaning machine is ready to start blasting ice on the dirty surface when needed.

2. Reduces Downtime

Most companies don't want production to stop because any time wasted is money lost. However, excessive accumulation of waste and dirt on the production line could interfere with the final products, which means that cleaning must be done regularly. However, some cleaning machines may fail to offer comprehensive cleaning within a short period, leading to downtime.

CO2 cleaning technology reduces equipment downtime. Additionally, equipment can be cleaned on site and without being disassembled, which means it can immediately resume production.

3. Environmentally Friendly

Dry ice cleaning is an environmentally sustainable cleaning strategy that food and chemical producing companies should consider. It is one of the safest cleaning methods available in the industry. There are no chemicals used in the entire cleaning process, which means that the environment is left clean and safe.

The use of carbon dioxide cleaning does not involve any water, hazardous waste, heat, or chemicals. This is an efficient and safe cleaning method, which makes considerable differences to the companies as they do not have to plan for harsh or abrasive cleaning solutions.

4. Dry Cleaning Process

Dry ice pressure washing is a dry cleaning process that does not leave any traces of water or moisture. The surface is left dry because all the dry ice vaporizes immediately after coming into contact with the cleaning surface. This means that you don't have to wait for the surface to dry.

The quick-drying process is highly appreciated in the electrical industry. Electronic industries prefer dry cleaning as it avoids electrical shocks and the short-circuiting that is likely to occur when water comes into contact with current-bearing wires. It is, therefore, a safe cleaning technique that does not expose people to harm.

5. No Allergies

As highlighted earlier, dry ice cleaning services do not use any form of chemicals. Neither does it use heat or any other form of industrial chemical that is likely to cause allergic reactions to people with asthma and other respiratory disorders. This explains why this form of cleaning is highly incorporated in hospitals, nursing facilities, and senior care facilities. You can as well use it around children as dry carbon dioxide does not have any health and safety issues.

Contact Us

For more information on mobilization and/or scheduling:

Call or text: 469-406-1542

All Rights Reserved | Interstate Carbonic Enterprises | Website by Olive Street Design