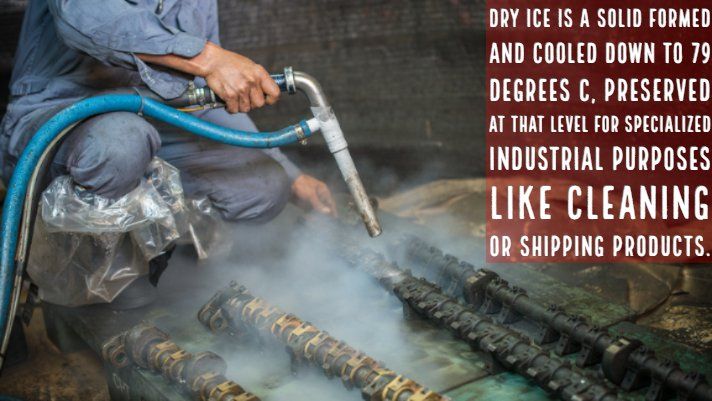

For those somewhat unfamiliar with dry ice blasting, the first step is to understand what it does not involve. There is no “ice” involved in the dry ice blasting process. Dry ice is not ice as we know it. It’s solid carbon dioxide at -79 degrees Celsius. While the name may bring to mind images of ice being hurled at a surface, that is not the case at all. It is more like a cloud of cold steam. But one of the best features of dry ice blasting is the fact that it involves environmentally sustainable cleaning. This makes it so regardless of the industry you are in, you can use this method of cleaning knowing that you are still doing your part to conserve the environment we depend on. There are more benefits as well, however. Here are a few of them.

It Is Fast

Speed is often seen as a luxury. After all, it is important to be careful and do a good job, even if that means taking a little more time. However, with dry ice blasting, you can have the best of both worlds: speed and efficiency. With this environmentally sustainable cleaning solution, you can often leave machinery in place while cleaning it. Due to the blasting process, you can still get into the little nooks and crannies that would normally necessitate the removal to the machinery. Keeping the equipment in place saves time and effort.

You can also keep important equipment assembled instead of taking it apart to clean it. If it is kept whole you save time because you don’t have to take it apart and then piece it back together again. And because of the intense blast you get during the cleaning, you are still able to access all of the hard to reach areas without going through the hassle of disassembly.

The Process Is Dry

So how can ice be dispersed and then instantly dry? Doesn’t ice have to melt? In fact, no, it does not. Perhaps you’ve seen ice disappear from the side of a road even if the outdoor temperatures never reached above freezing. When this happens—when a solid goes straight into a gas—it is called sublimation. In effect, the material “skips a step,” so instead of “melting” into a liquid and then heating up to the point where it evaporates, dry ice, when blasted, sublimates straight into a gas. This also helps make dry ice blasting environmentally sustainable cleaning because there is no run-off that could carry grease, oil, or other substances that had to be cleaned away into the local water supply or ecosystem. Further, because there is no liquid byproduct, material on the floor of a shop, factory, store, or warehouse that you don’t want to ooze into the water system can be kept in place and cleaned up at your leisure. In other words, you don’t have to clean up before cleaning.

Won’t Scratch Delicate Surfaces

Getting things clean often involves carefully scraping away at the unwanted substances. This has to be done with care, particularly if you’re trying to practice environmentally sustainable cleaning. However, no matter how careful you are, it is nearly impossible to avoid scraping and scratching valuable surfaces with most forms of cleaning. On the other hand, dry ice blasting won’t damage sensitive surfaces. This is because it is a non-abrasive process. The carbon dioxide that is shot at the surface gets the unwanted stuff off delicately. With the use of dry ice blasting, you can clean even very delicate surfaces such as fruits and vegetables without having to worry about ruining the product. Delicate paints and other fragile finishes can be taken care of using this environmentally safe cleaning method without you having to worry about marring the surface or otherwise ruining the product’s presentation.

Ice blasting has advantages that many other solutions lack. The speed at which the cleaning can happen, coupled with the dryness of the process and the safe nature of the blasting process make it an obvious choice for many different types of industries. Whether you deal with food, machinery, toys, or delicate goods, you can find a dry ice blasting solution for your needs.

Contact Us

For more information on mobilization and/or scheduling:

Call or text: 469-406-1542

All Rights Reserved | Interstate Carbonic Enterprises | Website by Olive Street Design