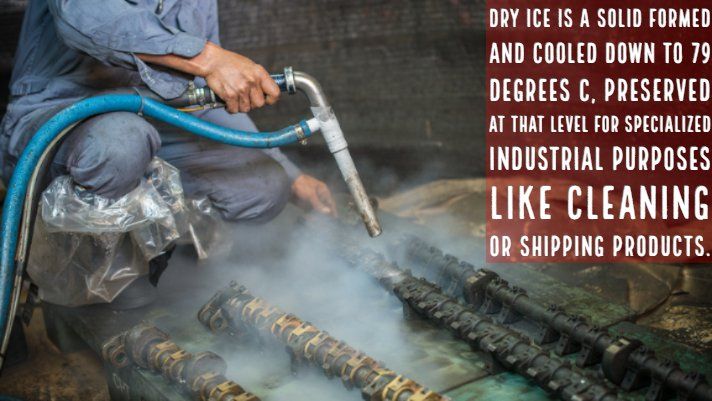

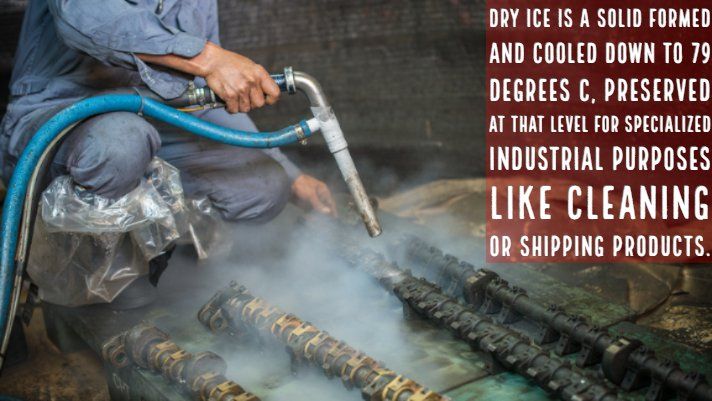

Dry ice cleaning, otherwise known as dry ice blasting, is a method started in 1955 of using dry ice to clean industrial equipment in an efficient and cost-effective way. According to Cold Jet , "Dry ice blasting is similar to sand blasting, plastic bead blasting or soda blasting where media is accelerated in a pressurized air stream to impact a surface to be cleaned or prepared."

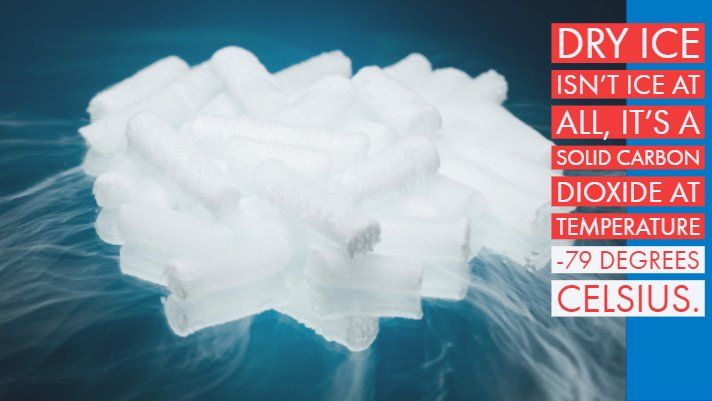

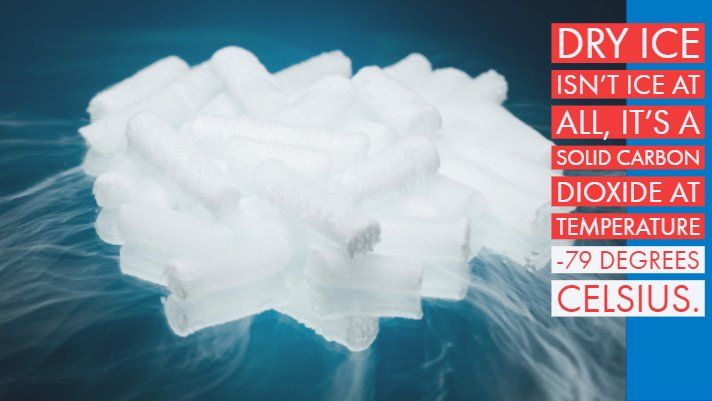

Even though its name may try to mislead you, dry ice actually is not ice at all. It is solid carbon dioxide that has been cooled down to -79 degrees Celsius. Although it is generally harmless, Carbon Dioxide is 40% heavier than the air we breathe and may change atmospheric conditions if the dry ice cleaning of generator is poorly ventilated.

Unlike traditional cleaning methods, dry ice blasting contractors provide quick results without damaging your equipment or taking systems offline for extended periods of time to remove cleaning remnants. The pellets actually evaporate on contact and leave behind no hazardous chemical residue for disposal. There is no need to wait for the solvents to dry before getting the machines back into service. Dry ice blasting for generators also allow the units to be cleaned in place without damage to cables and insulation.

The advantages do not just stop there for your dry ice cleaning of generator. Normal liquid cleaning methods leave the possibility for mildew or mold because of all the vapors and moisture in the air. With dry ice cleaning services, there is none of that. Sandblasting and other abrasive methods always have the potential to damage equipment that needs to be handled carefully. No worries there as well.

If you work in the food industry, dry ice blasting has been approved for use in that line of work. In fact, the Food Standards Agency found that dry ice blasting helped effectively decontaminate surfaces of Salmonella, E. coli, and Listeria monocytogenes. Overall, it is environmentally responsible because it contains no secondary contaminants. With dry ice cleaning of generator, there is no worries about fire hazards because it is a completely non-flammable and non-conductive cleaning method. It can be used without damaging active electrical or mechanical parts as well as to remove production residue, release agents, contaminants, paints, and oils that have been built up in hard to reach areas. Overall, dry ice blasting can be used for many general cleaning needs.

Because of the nonabrasive nature of dry ice cleaning, the method is often used in conservation and historical preservation projects. It is also very handy in manufacturing services like cleaning printing presses, weld lines, and molds. With all of these cleaning uses that normally have to do with productions and manufacturing, you would think that dry ice blasting made its debut in a factory, but it is actually believed to start with the U.S. Navy in 1945 as a means to get rid of grease.

AS mentioned earlier, the carbon dioxide that makes up the dry ice is not toxic, but that does not mean you can freely breath it in. If you are blasting it in an enclosed space, with no vents or windows near the floor (because it is heavier than oxygen, it only falls down, not float up) you can end up battling a case of asphyxia. If you are ever dry ice cleaning of generator, be sure to always wear insulated gloves as well as eye and ear protection. Your body will not be able to handle the -78 degree Celsius temperature of the gases.

Overall, dry ice blasting has been an effective and efficient method of cleaning materials for over the last 70 years. It is handy by not needing to fully deconstruct machines, while also not raising any concerns over flame or electrical hazards. Compared to liquid solvent cleaning methods, dry ice cleaning should be heavily considered for your next machine needing cleaning, no matter the industry you work in.

Contact Us

For more information on mobilization and/or scheduling:

Call or text: 469-406-1542

All Rights Reserved | Interstate Carbonic Enterprises | Website by Olive Street Design